Manufacturers from across the industry celebrate the multifaceted material polypropylene (PP) as the Swiss Army Knife of the polymer world. Renowned for its eclectic mix of attributes ranging from thermal resistance to chemical inertness, PP has emerged as a cornerstone in the domains of engineering and manufacturing. But beyond its mechanical potential, PP encapsulates a steadfast commitment to sustainability with a growing roster of eco-friendly applications. Follow along as we explore polypropylene’s various applications and properties, illustrating how this polymer is helping to build a greener tomorrow.

Delving Into Polypropylene’s Material Palette

Polypropylene, a thermoplastic polymer, has carved a dominant niche in various industries, largely due to its remarkable mechanical strength and chemical properties, making it a versatile option for multiple applications. PP is virtually inert and highly resistant to many acids, alkalis, and solvents. It’s an optimal choice for containers and vessels used to store a diverse range of substances. PP is a light, flexible material that allows for moldability and is not susceptible to fatigue under constant loads.

Unpacking the Properties

The engineering value of PP lies in its exceptional properties. Its high melting point makes it particularly useful for applications requiring a robust material that can withstand high temperatures. PP also offers a combination of high stiffness and toughness, making it an excellent material for products that experience incremental wear and tear. Furthermore, its low density translates to lightweight products that are easily transportable and handleable.

Constructing the Foundations of Engineering With Polypropylene

Polypropylene is essential in construction, machinery, and consumer products. Thanks to its insulation and electrical resistance properties, PP is a prominent constituent in electrical fittings and appliances. The polymer’s moldability and chemical resistance find a perfect synergy in automotive applications across interiors, battery casings, and bumpers. Mechanical and chemical engineers value PP for its ability to withstand a host of corrosive environments, making it an ideal candidate for pipes, tanks, and various equipment.

Exploring Everyday Products With Polypropylene’s Presence

The consumer marketplace is brimming with everyday products that stealthily owe their functionality to PP. The polymer plays an important role in ensuring the quality, longevity, and safety of several items. It’s the hidden hero in several products that are part and parcel of our daily lives.

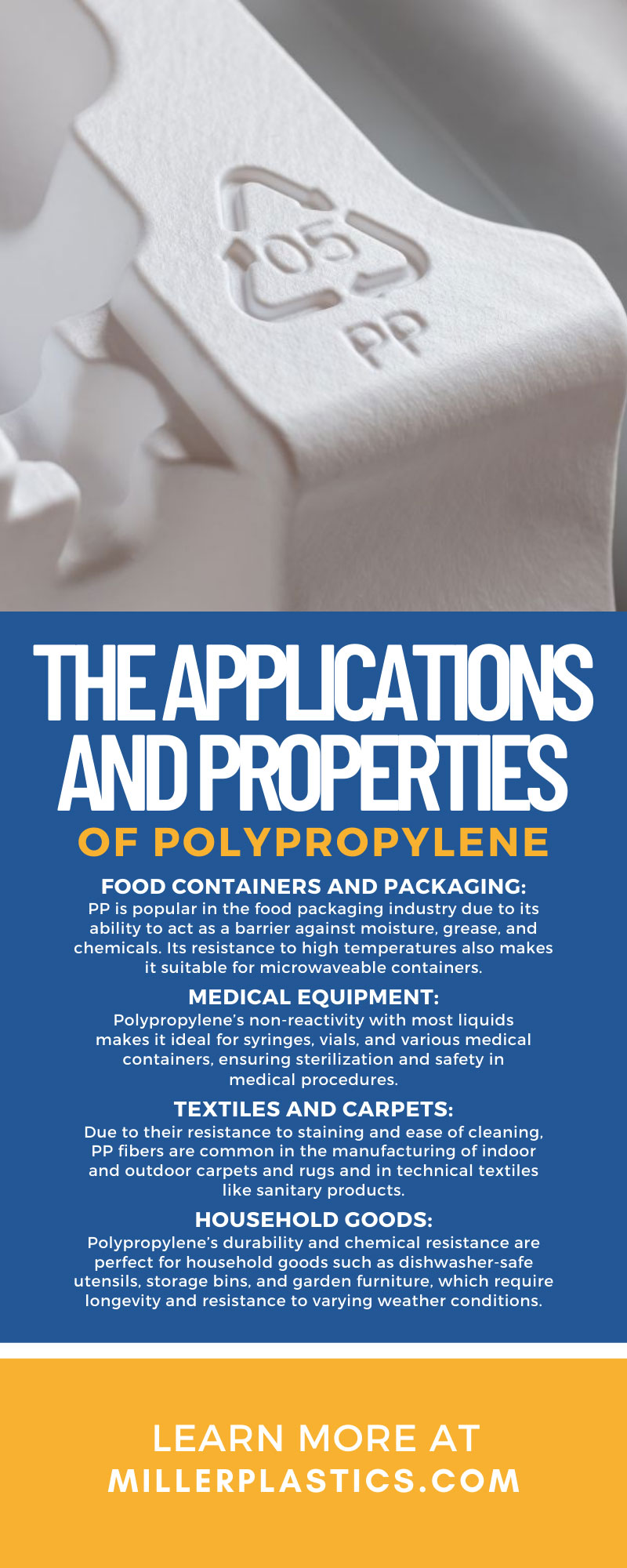

- Food Containers and Packaging: PP is popular in the food packaging industry due to its ability to act as a barrier against moisture, grease, and chemicals. Its resistance to high temperatures also makes it suitable for microwaveable containers.

- Medical Equipment: Polypropylene’s non-reactivity with most liquids makes it ideal for syringes, vials, and various medical containers, ensuring sterilization and safety in medical procedures.

- Textiles and Carpets: Due to their resistance to staining and ease of cleaning, PP fibers are common in the manufacturing of indoor and outdoor carpets and rugs and in technical textiles like sanitary products.

- Household Goods: Polypropylene’s durability and chemical resistance are perfect for household goods such as dishwasher-safe utensils, storage bins, and garden furniture, which require longevity and resistance to varying weather conditions.

- Sporting Goods: The lightweight and impact resistance of PP make it a material of choice for items like sports helmets, rackets, and protective gear, providing safety and comfort with minimal bulk.

- Automotive Components: The polymer is integral to the creation of crucial components such as battery casings, interior trims and pans, and bumpers and fenders.

Polypropylene’s versatility extends its use beyond the realm of engineering, permeating into various industries that benefit from its unique properties.

Sustainable Engineering with Polypropylene

The eco-conscious surge in engineering gives polypropylene a pivotal role in creating sustainable products and solutions. Due to its inherent durability, many products crafted from PP enjoy a longer lifespan, reducing the frequency of replacements. Additionally, PP’s recyclability contributes substantially to material conservation and waste reduction.

PP’s capacity for recycling into secondary products prolongs its lifecycle, reducing the environmental footprint. The production process for PP is efficient, with relatively low emissions compared to other polymers. Durable PP products last longer, which translates to less discarded material over time. This approach is pivotal in today’s environmental context. The extended lifecycle of PP products directly contributes to the reduction of waste reaching landfills, easing the strain on waste management systems and diminishing the environmental footprint of consumer goods.

Addressing the Challenges of Polypropylene Use

Despite its myriad advantages, using polypropylene is not without its challenges. One of the most significant challenges is ensuring that the recycling infrastructure can accommodate the variety of complex products made from PP. Additionally, certain industrial processes require extensive material testing to ensure that PP is the best choice among competing materials.

Infrastructure Upgrades

The recycling industry needs to upgrade its infrastructure to handle the diversity of PP-based products. Whether it’s a polypropylene tank for heavy industry or a household product, this requires cooperation between manufacturers, recyclers, and consumers to improve sorting methods that can separate various types of PP.

Research and Development

The versatility of PP’s properties means that it finds itself in competition with a significant number of other materials. Extensive research is needed to understand each material’s comparative strengths and limitations.

Innovation in Material Testing

Engineers and manufacturers are continuously innovating to facilitate easier selections of PP for different applications. This innovation process involves rigorously developing techniques to test PP-based products, ensuring their compatibility with diverse industrial and environmental conditions.

Future Trends and Innovations in Polypropylene Applications

Polypropylene’s future is entwined with innovation in manufacturing and product design. Additive manufacturing, also known as 3D printing, is an emerging realm exploring PP’s properties to create bespoke industrial components and consumer goods. The development of biodegradable PP is also on the horizon, promising a material that combines the attributes of traditional PP with an environmentally friendly disposition.

The Horizon Beckons

The potential for future PP innovations is vast. Engineers are experimenting with PP filaments for 3D printing, opening new avenues for customized products. Research into modifying PP for biodegradability without sacrificing performance is a promising frontier. This also includes advancements in compounding techniques and incorporating additives to enhance PP’s properties and make them suitable for specialized applications. With so many benefits, it’s easy to see why so many manufacturers are turning to PP for their production needs.

The Polypropylene Promise

Polypropylene’s reach extends across the domains of engineering, manufacturing, and even sustainability. Its thermoplastic nature caters to the exigencies of form and function and underscores a commitment to environmental responsibility. With every innovation, polypropylene solidifies its place as a material, not just for today but for the future we engineer. By taking time to explore the various applications and properties of polypropylene, you can make the most of your investment.