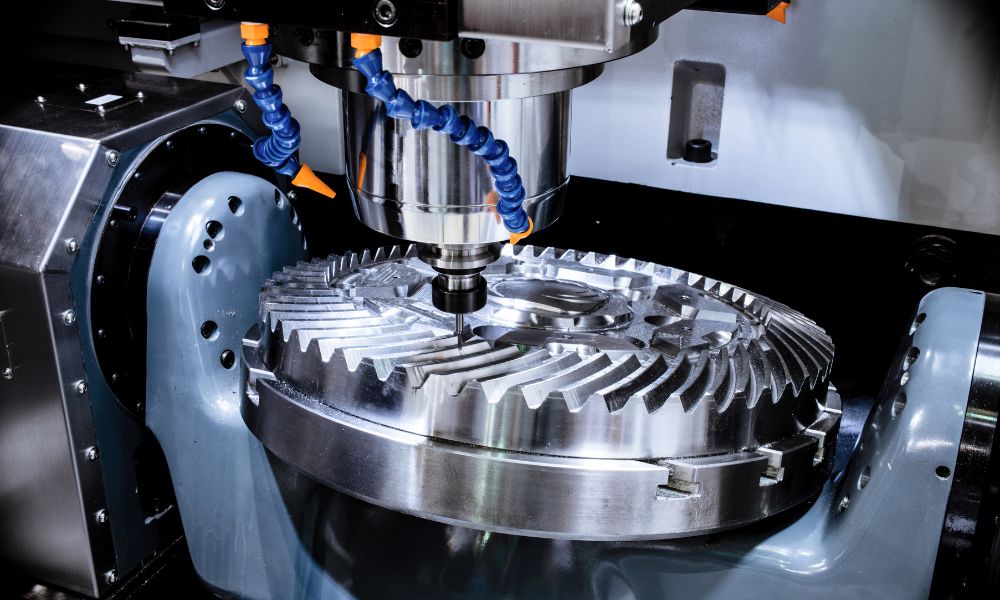

CNC machining is a widely embraced manufacturing technology used across diverse industries, including automotive, aerospace, and electronics. Despite its increasing popularity, misconceptions still surround this cutting-edge technique. We’re here to dispel some of the most common myths surrounding CNC machining and shed some light on the many benefits it can bring to your business.

Myth 1: CNC Machining Is Just for Metal

While it’s true that CNC machining has its roots in metalworking, this fabrication method has evolved to accommodate a variety of materials, including plastics, ceramics, and composites. CNC plastic cutting, for example, has become an integral part of the plastics industry, as it enables intricate designs, tight tolerances, and efficient mass production.

Myth 2: CNC Machines Are Costly

Initial investments in CNC machines can be substantial, but on a larger scale, this advanced technology allows manufacturers to save on overall production costs. CNC machining is highly accurate and efficient. It reduces material waste and eliminates the need for manual, labor-intensive tasks. These savings translate to long-term cost savings that manufacturers can reinvest in other areas of their business.

Myth 3: Skilled Machinists Will Become Obsolete

It’s a common fear that automation and technological advancement will push skilled workers out of their jobs. However, these worries are largely unfounded when it comes to CNC machining. The industry will always need skilled machinists to run and maintain machines, interpret designs, and manage quality control. In fact, as CNC machining becomes more prevalent, demand for skilled workers with the ability to operate and troubleshoot the equipment will continue to rise.

Myth 4: CNC Machining Is Bad for the Environment

Every production process has some degree of environmental impact. But CNC machining has taken significant strides in reducing its ecological footprint. By using modern, energy-efficient machines, advanced software, and precise cutting tools, CNC processes consume less power and generate less waste than many traditional manufacturing methods. As a result, CNC machining is steadily becoming a more sustainable solution for a variety of industries.

We’ve debunked some of the most common myths surrounding CNC machining. Armed with this knowledge, we encourage you to explore the world of CNC plastic cutting and beyond. As your partner in all things fabrication, Miller Plastics offers state-of-the-art CNC plastic cutting services to help you realize your most ambitious design and production goals. Reach out to us today to discuss your project needs!