What’s the Difference?

Manufacturers have various techniques to take your custom part from design concept to reality. Here’s how you can distinguish between two of the most popular methods.

Machining

This is also called CNC (Computer Numerical Control) machining or subtractive manufacturing. Specialized equipment is programmed to cut away material from a solid plastic “blank” until it achieves the desired shape.

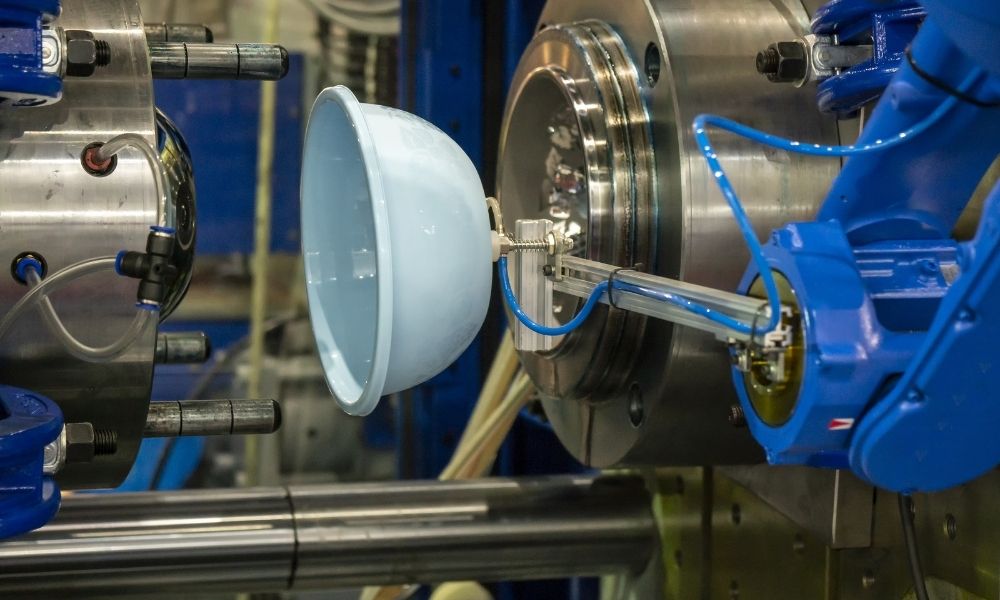

Injection Molding

Your specialist will craft a mold for your part. Once the plastic pellets are heated to their melting point, they are squeezed into the cavity. As they cool, the plastic takes on the shape of the mold.

How Do You Decide?

The right method is usually obvious once you consider the nature of your project. Some of the key questions include:

Adjustments

Is it possible that you’ll need to alter the design of your custom part? In that case, plastic machining servicesare the better choice becauseit’s easier to make adjustments.You just have to reprogram the machinery, not start from scratch with a new mold.

Number of Parts

If you’re producing thousands of parts, injection molding is probably the way to go. While the up-front cost of making a mold can be expensive—especially if it’s intricate—the manufacturing itself is less expensive in the long run. But if you only need a few hundred parts or less, it doesn’t make sense to pay for a mold.

Precision

Both production techniques are highly accurate. For instance, injection molding will form your custom part within .005 inches of specifications, but machining can top that: it comes within .001 of specifications. So, if you need the part for something critical, like a rocket ship, machining will give you more precision.

Aesthetics

When you remove cooled plastic from a mold, you’re likely to have imperfections, such as a seam. “Knockout pins” are used to force the part out, which can leave small depressions. If that’s not acceptable and you need a pristinely smooth surface, plastic machining will do the trick.

Material

As you’re choosing the best plastic for your part, keep in mind that fewer of them are suited to injection molding. More flexible plastics do well in molds, but harder, high-performance plastics are better for machining.

Don’t worry—you won’t have to make the decision on your own. When it comes to plastic machining parts vs. plastic injection molding, Miller Plastics can advise you on the ideal production technique. Contact us with more questions or to discuss your project.