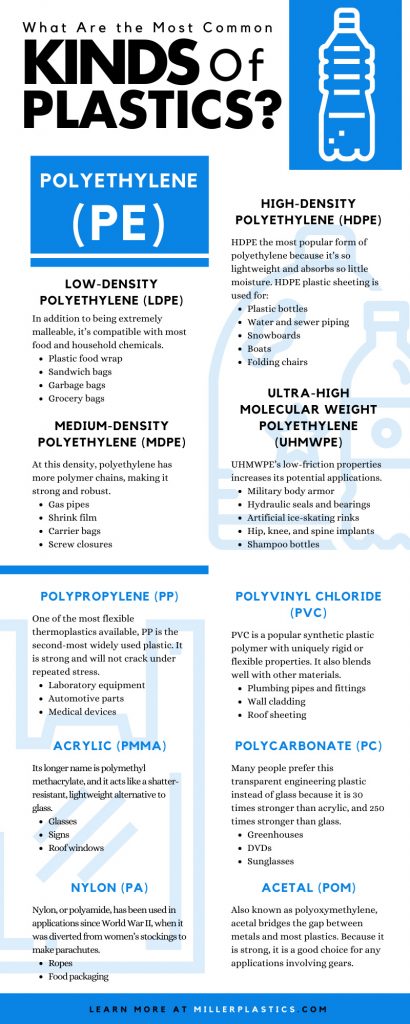

While we use the word “plastic” all the time, there are actually dozens of materials that fall under this category. Each has its own properties, so project managers have plenty of choices when it comes time to manufacture. But what are the most common kinds of plastics? Even if you don’t know their names, you’ve probably seen them in action.

Polyethylene (PE)

Polyethylene is the most commonly used plastic on earth, as it is incredibly versatile. People can use it for a wide range of applications. It’s available in four densities, each with its own properties.

Low-Density Polyethylene (LDPE)

This transparent form of polyethylene can be hammered thin and even drawn out into a thread without breaking. In addition to being extremely malleable, it’s compatible with most food and household chemicals. A few applications include:

- Plastic food wrap

- Sandwich bags

- Garbage bags

- Grocery bags

- Squeeze bottles

- Irrigation tubes

- Garbage bins

Medium-Density Polyethylene (MDPE)

At this density, polyethylene has more polymer chains, making it strong and robust. It has a higher stress-cracking resistance than HDPE (below), making it the better choice for some projects. Among its uses:

- Gas pipes

- Shrink film

- Carrier bags

- Screw closures

High-Density Polyethylene (HDPE)

HDPE the most popular form of polyethylene because it’s so lightweight and absorbs so little moisture. HDPE plastic sheeting is used for:

- Plastic bottles

- Water and sewer piping

- Snowboards

- Boats

- Folding chairs

Ultra-High Molecular Weight Polyethylene (UHMWPE)

Although not much denser than HDPE, this plastic has much longer polymer chains that make it more resistant to abrasion. UHMWPE’s low-friction properties increases its potential applications. Its uses include:

- Military body armor

- Hydraulic seals and bearings

- Artificial ice-skating rinks

- Hip, knee, and spine implants

- Shampoo bottles

- Soap bottles

- Detergent and bleach containers

- Agricultural pipes

Polypropylene (PP)

One of the most flexible thermoplastics available, PP is the second-most widely used plastic. It is strong and will not crack under repeated stress. It resists heat and acid and is extremely durable. You will find it in:

- Laboratory equipment

- Automotive parts

- Medical devices

- Ice cream tubs

- Margarine tubs

- Potato chip bags

- Straws

- Microwave meal trays

- Garden furniture

- Lunch boxes

- Prescription bottles

- Blue packing tape

Polyvinyl Chloride (PVC)

PVC is a popular synthetic plastic polymer with uniquely rigid or flexible properties. It also blends well with other materials. PVC-U is the unplasticized and more rigid version. It is used for:

- Plumbing pipes and fittings

- Wall cladding

- Roof sheeting

- Cosmetic containers

- Bottles

- Window frames

- Door frames

PVC-P is the softer and more flexible plasticized form of PVC. It is commonly used for:

- Cable sheathing

- Blood bags

- Blood tubing

- Watch straps

- Garden hoses

- Shoe soles

- Electrical cable insulation

Chlorinated Polyvinyl Chloride (CPVC)

CPVC acts like a cousin to PVC. The chlorination process helps the plastic withstand a wider range of temperatures, and it is often required by code for hot water pipes. PVC is not approved for applications at more than 140 degrees Fahrenheit, but CPVC can handle temperatures of up to 200 degrees. It is also resistant to many corrosive chemicals. CPVC is used for:

- Pumps

- Valves

- Strainers

- Filters

- Tower packing

- Ducts

- Storage tank linings

- Fume scrubbers

Acrylic (PMMA)

Its longer name is polymethyl methacrylate, and it acts like a shatter-resistant, lightweight alternative to glass. Acrylic is ideal for optical devices because of its convenient properties: in sheet form, it can be transparent, scratch-resistant, UV-tolerant, non-glare, anti-static, impact-resistant, and much easier to handle than glass. Among its uses:

- Glasses

- Signs

- Roof windows

- Mirrors

- Plexiglass

Polycarbonate (PC)

Many people prefer this transparent engineering plastic instead of glass because it is 30 times stronger than acrylic, and 250 times stronger than glass. PC is tough and stable, and suitable for many plastic machining services. It can be worked, molded, thermo-formed, and cold-formed. It is often used for:

- Greenhouses

- DVDs

- Sunglasses

- Police riot gear

Ertalyte®

This thermoplastic polyester is based on polyethylene terephthalate (PET-P). It is more rigid and has greater thermal performance than nylon and acetal. It works well in both wet and dry environments, has a low coefficient of friction, and can endure long wear. You’ll find Ertalyte® used for:

- Food processing equipment components

- Process and test equipment manifolds

- Carousels

- Filter tracks

- Rings, disks, rollers

- Fuel pump components

- Fuel system connectors and rotors

Acetal (POM)

Also known as polyoxymethylene, acetal bridges the gap between metals and most plastics. Because it is strong, it is a good choice for any applications involving gears. It is also resistant to heat, abrasion, water and chemicals. Among its uses:

- Gear wheels

- Eyeglasses

- Ball bearing and locking systems

- Yo-yos

- Zippers

- Keyboard key caps

Nylon (PA)

Nylon, or polyamide, has been used in applications since World War II, when it was diverted from women’s stockings to make parachutes. It is high-strength, lightweight, and it can resist high temperatures. It is compatible with many chemicals. It is used for:

- Ropes

- Food packaging

- Powder coating

- Instrument strings

- Guns and rifles

- Combs

- Tires

- Toothbrushes

Vespel®

This plastic is useful in hostile conditions because it combines heat resistance, dimensional stability, creep resistance, and natural lubricity. It is even resistant to radiation. Vespel® has helped develop the fields of aerospace, semiconductor, and transportation. Its applications include:

- Bushings

- Valve seats

- Plungers

- Thermal and electrical insulators

- Vacuum pads

These are the most common kinds of plastics, but what do they have in common? They are all at least partially synthetic, with polymers as a main ingredient. It is hard to know when new plastics will be developed, but researchers at the U.S. Department of Energy are concentrating on plastics that are completely recyclable.

Every project has its own unique requirements. Fortunately, there are so many different plastics to choose from, with varying properties. In a way, they each have their own personality. While there may not always be a perfect match, Miller Plastics can help you weigh the pros and cons of different materials until you arrive at the best choice for your customized plastic parts. Contact us or stop into our facilities in Burgettstown, Penn., near Pittsburgh. We can be your guide through the ever-changing world of plastics and technology.