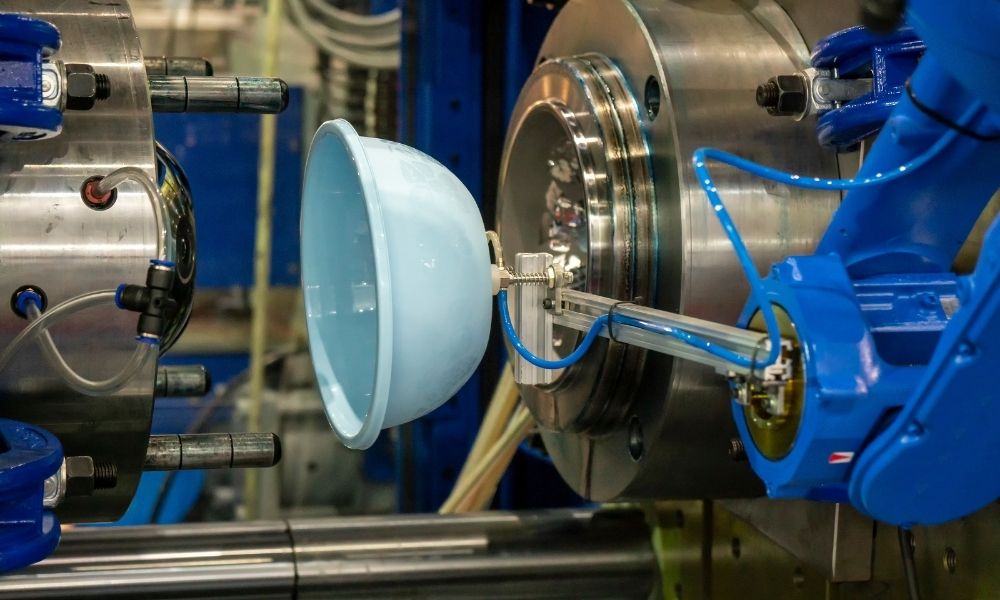

If you’ve ever worked with plastic fabrication, you know how technical this process can be. It seems like you’re constantly inspecting or adjusting something throughout your shift to ensure that everything is running smoothly and the product remains consistent throughout production. These are a few tips to extend the life of your plastic fabrication machines so that you can get the most out of your equipment.

Think About Materials

Parts are always an expense, and as you’re using parts to create other parts, you may need to learn how to pinch pennies to make a profit. Balancing the budget can complicate plastic parts fabrication, but it doesn’t have to. Many companies who produce plastic now integrate other materials into their molds to help cut back on the weight, limit the amount of polymer used, and improve the product’s performance. Adding an inexpensive material like reinforced glass fiber helps to strengthen and give the flexibility that the polymers usually would not have.

Protective Coating

Some manufacturers coat their internal molds and fabrication pieces with carbon coatings. This technique has significantly reduced the wear and tear on the machine parts that can cost tens of thousands of dollars to replace. It also creates a synthetic lubricant effect, although there is no lubricant present. The carbon layer becomes slick under high temperatures, allowing the molds to slide in and out uniformly. This prevents any residue or formation of byproducts after long shifts of building plastics.

Proper Cooling Techniques

Many manufacturers fail to think about the cooling temperatures for setting the plastic properly. If your machines aren’t operating at the proper speeds and ranges, you will spend more hard-earned money making sub-par products. To allow your pieces to set correctly, make sure you’re inspecting at least three times a day during a shift at breakfast, lunch, and before the end of the shift change to ensure that the cooling process doesn’t exceed 5 degrees Fahrenheit. Simple additions to managing your business like this will help things move smoothly as you go along.

Implement any of these tips to extend the life of your plastic fabrication machines. Use them, and you will see how much they can help your business thrive.