Since plastics were first developed several decades ago, they have benefited us in more ways than we can imagine. It goes without saying that they have a place in the world and will continue to serve us well into the future. Here are five reasons you should switch from metal parts to plastic to ensure the best possible results.

Plastic Doesn’t Biodegrade

Environmentalists will argue that this is a contributing factor to climate issues today. But if we focus on the manufacturing benefits that plastic provides, we can start to recognize it as a beneficial material.

Plastics can remain functional for extended periods of time without breaking down. Metals can corrode and rust as they oxidize, so they are only good for a limited time. As such, plastic parts are often more beneficial than metal in some scenarios.

Plastic Is Lighter

You might think that plastics lack strength and durability due to their lack of density. But the reality is that polymers are almost as strong as some metals.

This light profile means that plastics are easier to work with and manage than metals. This is a huge advantage, as it requires less labor and manpower to construct and maintain mechanical builds that utilize plastic parts.

Cheaper Production

Plastics are produced from a resin byproduct derived from producing petroleum from crude oil. This makes plastics incredibly cheap to create, and they can often be manufactured at an incredibly low percentage for the amount of fuel that is being produced. Thus, it is a verifiable option that costs much less than any metal used for the same purposes.

Plastic Is More Flexible

Metals aren’t exactly known for their flexibility. The hardness of a specific metal typically determines how flexible it will be.

If the metal is too hard, it will not be able to bend and can shatter and break under extreme stress and pressure. So, plastics win again when it comes to flexibility.

Plastic Is Heat Resistant

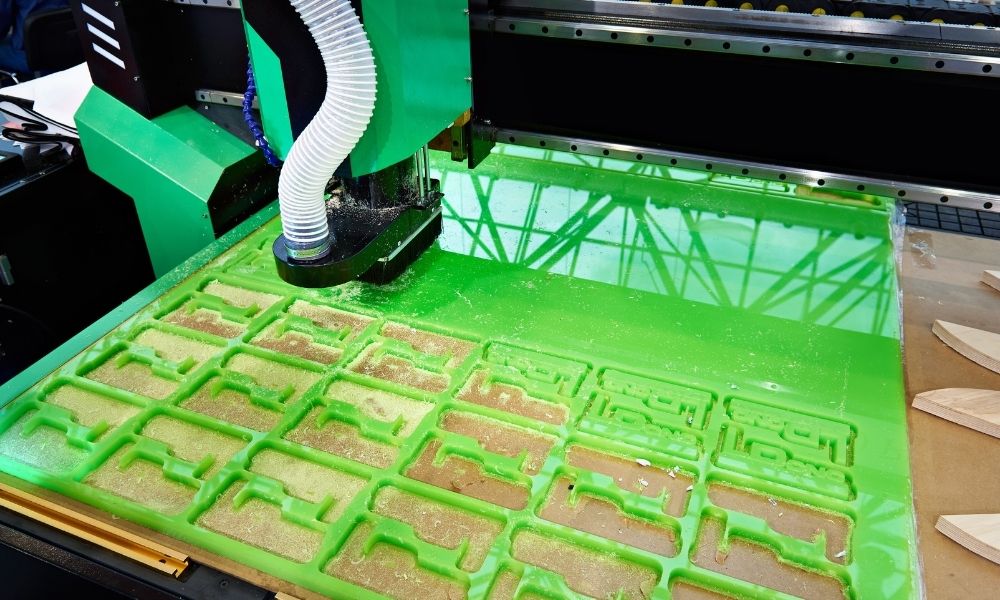

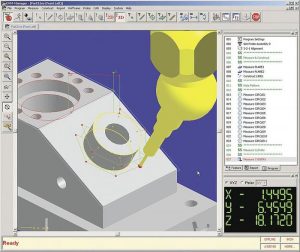

Many plastics are produced using CNC plastics machining services through a method called thermoforming, meaning that they are heat-treated to a certain degree. This means they are able to withstand the same temperatures that many metals are subjected to, enabling these plastic parts to be used in production and as mechanical gears and aids.

After learning about all the benefits and attributes of plastic polymers, you might consider making the change to plastics. This list has explained five reasons you should switch from metals to plastics, but polymers actually have many more benefits and abilities, and more are being discovered daily. Therefore, they are well worth the investment.